mepramo

Newbie level 3

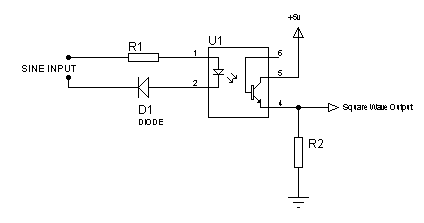

I am doing a project where i need to find the frequency of a waveform generated by a spark plug. I am using pic 16f 877a & ccs compiler for programming. As a beginning am trying to assume that the wavform to be measured is a sine. And convert it into an adc and make it square, & find the frequency.i am beginner in this field and am nt able to programme it.