Cap_J

Newbie

Hello,

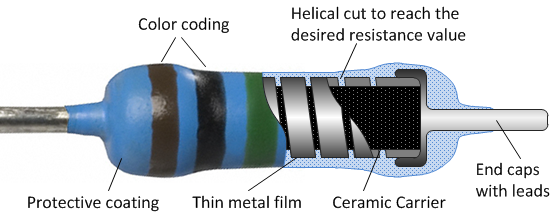

I would like to identify the type of resistor in the photo on the left.

After removing the paint, I can see a dark/graphite cylinder with a short "bar" (gouge/cut). Would this be a carbon resistor? Unfortunately I wasn't able to cut/split it with pliers to check the inside.

Thank you in advance for your answers.

Regards.

I would like to identify the type of resistor in the photo on the left.

After removing the paint, I can see a dark/graphite cylinder with a short "bar" (gouge/cut). Would this be a carbon resistor? Unfortunately I wasn't able to cut/split it with pliers to check the inside.

Thank you in advance for your answers.

Regards.