- Joined

- Jan 22, 2008

- Messages

- 52,374

- Helped

- 14,746

- Reputation

- 29,774

- Reaction score

- 14,087

- Trophy points

- 1,393

- Location

- Bochum, Germany

- Activity points

- 297,885

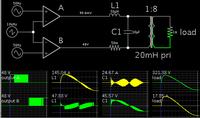

I presume Falstad doesn't use a saturable core in the standard transformer model (other circuit simulators do neither, and it's always a bit demanding to find the right core parameters if you use such a model).On the other hand, if you start the SPWM at the 90 or 270 degree mark, then you expose all components to peak current abruptly.

But if you have a saturable core, then the sine voltage should be in fact started at 90 or 270 degree to avoid saturation (You want a symmetrical flux ∫Vdt, so you start with half the area). Of course this contradicts the idea of smooth filter capacitor start current.

So yes, a voltage ramp is probably the most simple solution. Alternatively, a fast saturation free start could use one halfwave of 50% magnitude and switch to 100% after the first zero crossing.