DeepOne

Advanced Member level 2

- Joined

- Feb 26, 2011

- Messages

- 632

- Helped

- 99

- Reputation

- 200

- Reaction score

- 100

- Trophy points

- 28

- Location

- 45N39E, Russia

- Activity points

- 0

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

answer yes. Now it worked only if АС connected.1. Does it run when AC is connected?

this brand named "Skil" is glorified by low quality of battery pack. So battery has served around several months. Afterwards I soldering new battery. But most of time device worked from external 6V acid battery because internal 0,8Ah 7,2V battery so little .2. How old is the battery pack? They only last a certain amount of time.

answer yes.3. Do you know if the battery pack gets any charge?

answer yes.4. Can you remove the batteries? Can you test what power they provide?

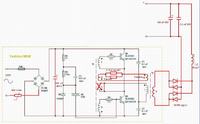

This scheme is AC-DC converter, so no need batteries .5. Does it run on AC with the batteries removed?

there signed in scheme. This is pack of 30A 50V shottky diodes, taken from old broken PC power supply.6. Did you circle the two components in the schematic? Zener diodes? Schottky diodes?

Happy crhistmas for all peaple of forum...

I have a drill cordless Bosch PSR 18VLi-2 new, but it not work because card module electronic system is broken and it is not repairable

Exactly, photographies of drill and battery entrails there be useful (please compress it for no more than 200kb sizes).I can to attach files and photo if you have need...

It is necessary to think twice previously than by-passing battery protection systems. However if battery not used that not important.check for overheating of the tool, did I want to know, how to by-pass this system

Unless imitate batteries presence on these central contacts that electronics most likely will not allow to work, particularly if take into account that card module electronic system is broken.can I connect 18V to the pins only + and - and to leave the two central pins free?

Happy Christmas ..

Happy Christmas ..obviously this is inexpensive low voltage mosfet, like IRLU024 N or IRLR024N (N-MOS 55V. 17A (Logic-Level)) If this mosfet perforated on G-S line that probably carry away else PIC16 microcontroller. If this suggestion is correctly that possible only use this card module as scrap, since MCU without program is useless.in board pcb is written as Q1.

Except this it is necessary to check condition of signal and power lines in accordance with this mosfet. Advisable also understand reason of this fet mortality.If I replace these two electronic components

For this it is necessary simply to take this switch and ask spare parts seller to find similar from standpoint of the sizes. Certainly if You have such seller around.can you help to find me a trigger Chinese compatible?

I shall begin with define of trigger switch input wires. If there is direct output from internal changeable resistor (three fine white wires)?which first step I must do?

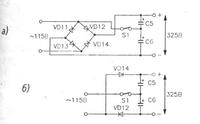

in such event possible to try to remake hf converter that for 12V lamps.i live in a place where we dont have electronic supplies

whorls amount possible to calculate manually, or with help of some program intended for this, or it may be selected experimentally.how would i change the number of whorls in primary winding

I don`t see this circuit for 120V but there not will too be a greater change from 220V circuit.is there perhaps another place you know where i can see the 120v circuit already built?

250W lighting ballast must be sufficient in most cases.maintaining the proper amouont of amps to sustain power to the drill

Probably better take the big iron transformer from unnecessary UPS and connect it with rectifier and output filtering chains. This will be simply, reliable and safely. But weighty )I am new to this.