powersys

Advanced Member level 1

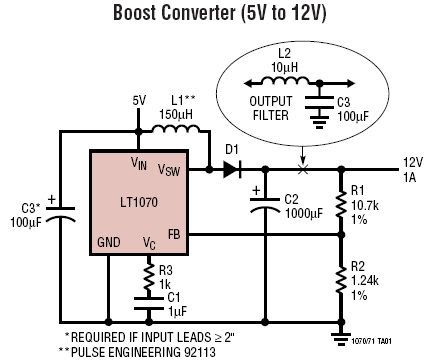

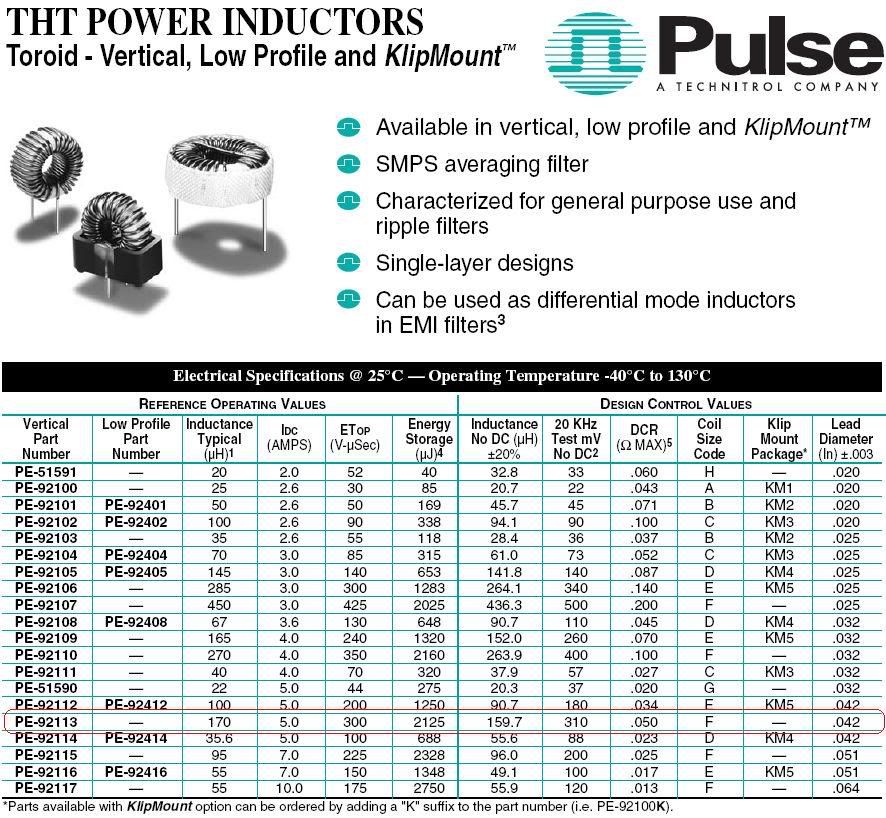

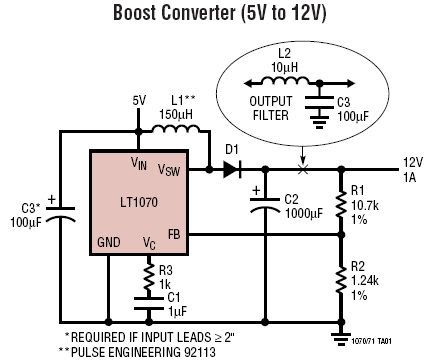

I wish to build a boost converter using LT1070 as shown in the 1st figure. The power inductor suggested by Linear Technology is PE-92113 from Pulse Engineering (pls refer to 2nd figure). Unfortunately, PE-92113 is not available in local market. Therefore, we wish to get a replacement for the inductor. However, as shown in 2nd figure, there are many parameters/specifications that describe an inductor. Besides the inductance value, which parameters are important and required to find an inductor (e.g. manufactured by C&D Technologies) that will match the performance of PE-92113 as close as possible?

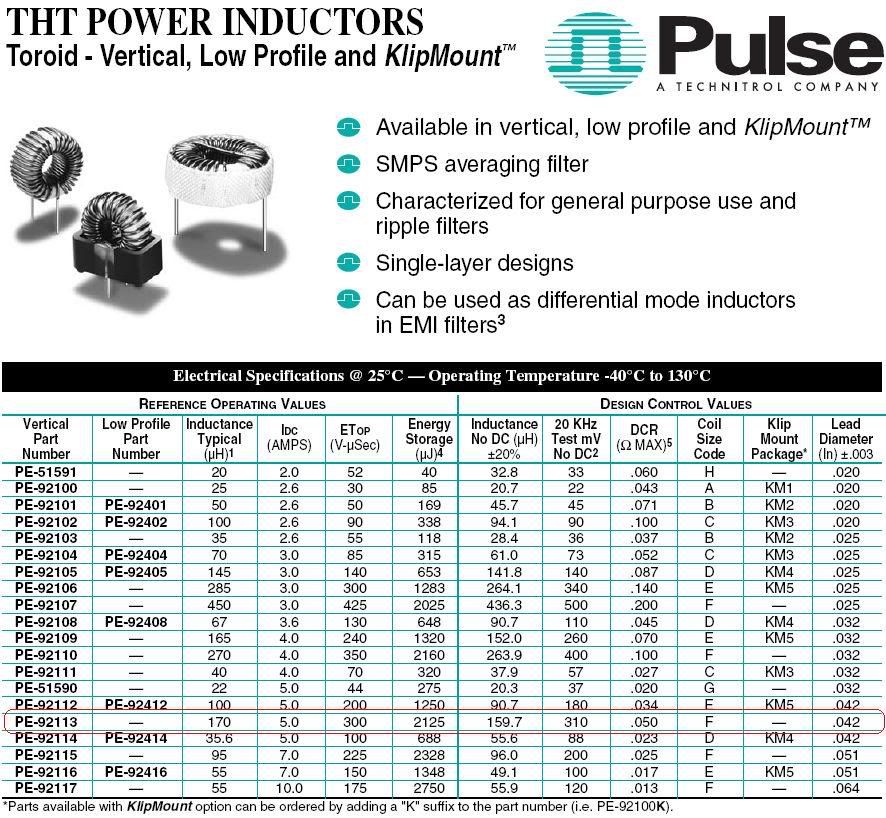

By the way, what is the difference between the following two inductances:

[3rd Column] Inductance Typical (uH)

[7th Column] Inductance No DC (uH) +/-20%

And, why the inductance value shown in 7th column is lower than that of 3rd column?

Thanks

By the way, what is the difference between the following two inductances:

[3rd Column] Inductance Typical (uH)

[7th Column] Inductance No DC (uH) +/-20%

And, why the inductance value shown in 7th column is lower than that of 3rd column?

Thanks