bhengsoh

Newbie level 6

Hi. I'm not sure if this is the right section but here's the problem I faced.

I am building a robot that will be guided to 3 different locations using infrared. What I'm planning to do is to have IR transmitter in each location to transmit modulated signal to the robot. My problem is how to design a circuit that can transmit different serial code through IR, and the robot can differentiate the signal from different IR source.

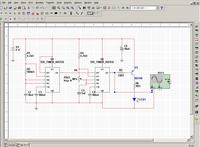

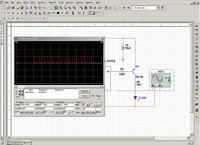

So far, what is in my mind is to use parallel to serial register IC to change into serial data, and modulate it using 555 timer. But I very unsure whether this is the correct way. If this is possible, what are the common IC available and how should the circuit look like:?: For receiving part, I will be using PIC16F877A microcontroller with IR receiver.

Another problem is how to make the robot stop like 1 meter before it reach the IR transmitter.

Pls give me your opinion. Ty.

I am building a robot that will be guided to 3 different locations using infrared. What I'm planning to do is to have IR transmitter in each location to transmit modulated signal to the robot. My problem is how to design a circuit that can transmit different serial code through IR, and the robot can differentiate the signal from different IR source.

So far, what is in my mind is to use parallel to serial register IC to change into serial data, and modulate it using 555 timer. But I very unsure whether this is the correct way. If this is possible, what are the common IC available and how should the circuit look like:?: For receiving part, I will be using PIC16F877A microcontroller with IR receiver.

Another problem is how to make the robot stop like 1 meter before it reach the IR transmitter.

Pls give me your opinion. Ty.