T

treez

Guest

Hello,

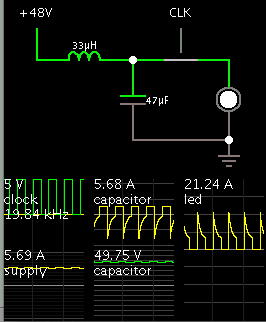

Where I work, they are just willy-nilly making connections to the equipment chassis as in the attached.

The obvious point is that since there are current flows between various sub-systems, their ground potentials are not the same. -But then these non-similar ground points are getting connected to earth at the bit of chassis that's near them.

What do you think of this? and how would you change it to correct it?

Where I work, they are just willy-nilly making connections to the equipment chassis as in the attached.

The obvious point is that since there are current flows between various sub-systems, their ground potentials are not the same. -But then these non-similar ground points are getting connected to earth at the bit of chassis that's near them.

What do you think of this? and how would you change it to correct it?