Electronics_chaitanya

Member level 5

Hello all friends

I am trying to make inductive proximity sensor.Sensing distance of 4-5mm is sufficient for me but i am not getting success in design.

As per theories provided on internet oscillations should be stopped or at least decrease when metal object in keep near coil of sensor but in my design when metal object is kept near sensor frequency of oscillation changes due to change in inductance of coil.but amplitude of oscillation is not decreasing.

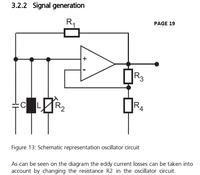

I am using simple colpitt oscillator and trying to observe if amplitude decrease or not.

I have following confusion

1) Why oscillations are not stopping? at which point i am wrong?

2) Which frequency should i use for oscillations? i am at 1Khz right now.(I am talking about frequency at which coil resonates.)

3) In some industrial designs i have seen tapped coil having 3 wires coming out i have even seen 4 wire coils(2 coils).What is reason of that?

4) Should i use Hartly oscillator or colpitt oscillator ? which are best suitable?

5) I have attached a circuit diagram having two coils.Is it works for proximity sensor design.I understand how it oscillates but i cant get to know what is function of inductor connected to base of oscillator transistor.

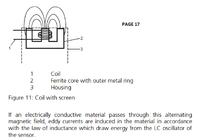

I have also attached oscillator i am using for my experiment as well as photo of inductor i have used.I cant found ferrite pot core.So core i have shown will work ? at least for this experiment? or i need to go for pot core?

Regards

I am trying to make inductive proximity sensor.Sensing distance of 4-5mm is sufficient for me but i am not getting success in design.

As per theories provided on internet oscillations should be stopped or at least decrease when metal object in keep near coil of sensor but in my design when metal object is kept near sensor frequency of oscillation changes due to change in inductance of coil.but amplitude of oscillation is not decreasing.

I am using simple colpitt oscillator and trying to observe if amplitude decrease or not.

I have following confusion

1) Why oscillations are not stopping? at which point i am wrong?

2) Which frequency should i use for oscillations? i am at 1Khz right now.(I am talking about frequency at which coil resonates.)

3) In some industrial designs i have seen tapped coil having 3 wires coming out i have even seen 4 wire coils(2 coils).What is reason of that?

4) Should i use Hartly oscillator or colpitt oscillator ? which are best suitable?

5) I have attached a circuit diagram having two coils.Is it works for proximity sensor design.I understand how it oscillates but i cant get to know what is function of inductor connected to base of oscillator transistor.

I have also attached oscillator i am using for my experiment as well as photo of inductor i have used.I cant found ferrite pot core.So core i have shown will work ? at least for this experiment? or i need to go for pot core?

Regards