xeratule

Member level 4

- Joined

- Apr 4, 2009

- Messages

- 69

- Helped

- 1

- Reputation

- 2

- Reaction score

- 1

- Trophy points

- 1,288

- Location

- Istanbul / TURKIYE

- Activity points

- 1,975

Hi all,

I am using high power (600V,12A @ 100°C) ultrafast IGBT's in a full bridge circuit configuration. The gates are driven with push pull PWM.

The IGBT's get overheated and fail when draining only 4.5A collector current. (Although IGBT's are bounded to a passive aluminium cooler with fan support).

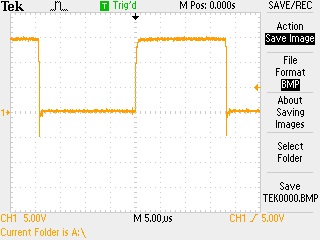

I know if PWM signal is not sharp at edges that will cause switching loss. The gate PWM signals seems sharp enough when I don't supply the collector of the IGBT's. When I supply with 220V (Vcc) and IGBT's start to drain current the gate signals get noisy. Please see the attached gate rising edge signal measurements with and without Vcc supply voltage. Do you think that causes the big portion of the temperature rise? What causes this ripples and how can I get rid of them?

Why else do they overheat?

Would like to hear from you soon. Thanks in advance.

Erhan

I am using high power (600V,12A @ 100°C) ultrafast IGBT's in a full bridge circuit configuration. The gates are driven with push pull PWM.

The IGBT's get overheated and fail when draining only 4.5A collector current. (Although IGBT's are bounded to a passive aluminium cooler with fan support).

I know if PWM signal is not sharp at edges that will cause switching loss. The gate PWM signals seems sharp enough when I don't supply the collector of the IGBT's. When I supply with 220V (Vcc) and IGBT's start to drain current the gate signals get noisy. Please see the attached gate rising edge signal measurements with and without Vcc supply voltage. Do you think that causes the big portion of the temperature rise? What causes this ripples and how can I get rid of them?

Why else do they overheat?

Would like to hear from you soon. Thanks in advance.

Erhan