grizedale

Advanced Member level 3

Hello

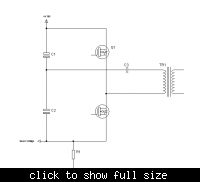

I must do half-bridge SMPS with vin = 390V and power = 200W

It must be very cheap so i dont want to have a current sense transformer as its expensive.

Instead i widh to have a current sense resistor, connected from the half bridge ground, back to the ground of the PFC

stage........i.e. the current sense resistor voltage goes below the ground of the half-bridge controller.

-howver, i cannot find a controller like this for half-bridge.

do you know why they don't exist.

This type of current sensing exists for LLC resonant controllers as in FAN7621.

I must do half-bridge SMPS with vin = 390V and power = 200W

It must be very cheap so i dont want to have a current sense transformer as its expensive.

Instead i widh to have a current sense resistor, connected from the half bridge ground, back to the ground of the PFC

stage........i.e. the current sense resistor voltage goes below the ground of the half-bridge controller.

-howver, i cannot find a controller like this for half-bridge.

do you know why they don't exist.

This type of current sensing exists for LLC resonant controllers as in FAN7621.