assu

Junior Member level 3

- Joined

- Dec 8, 2011

- Messages

- 28

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 1,281

- Location

- PAKISTAN

- Activity points

- 1,508

Greetings,

I have solar panel which produces following

Vmp=16V

Imp=7.5A

P=120W

Battery to be charged is 12V 45Ah Lead Acid

Now, I will be charging the battery at 14V and 5Amp (i.e., approx 10% of 45Amp)

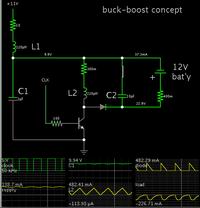

I have found buck converter would be feasible for this solution but on the other hand if

PV Panel reduces its voltage to 12V due to less sunlight so i will have to boost the voltage while bargaining current less than 5amp

So should i design buck/boost OR Cuk converter for it. As many sources say Cuk is most reliable.

I have solar panel which produces following

Vmp=16V

Imp=7.5A

P=120W

Battery to be charged is 12V 45Ah Lead Acid

Now, I will be charging the battery at 14V and 5Amp (i.e., approx 10% of 45Amp)

I have found buck converter would be feasible for this solution but on the other hand if

PV Panel reduces its voltage to 12V due to less sunlight so i will have to boost the voltage while bargaining current less than 5amp

So should i design buck/boost OR Cuk converter for it. As many sources say Cuk is most reliable.