rahulpsharma

Junior Member level 2

Hello,

I dont wish to use a Microcontroller... (Cos I donno abt it.. .. ) I just wish to keep it simple but fairly accurate... Following is what I am looking for:

.. ) I just wish to keep it simple but fairly accurate... Following is what I am looking for:

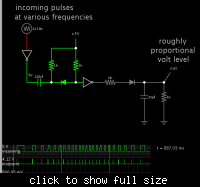

Pulses of varying width will be generated from an optocoupler connected to a Wind Speed Sensor... These pulses needs to be converted using a curcuit to a DC Voltage of, say, 0 - 1V... For low speed, the pulse width will be long and for high speed, pulse width will bee short.... I am planning to have some trim pots to finally calibrate the wind sensor using a reference instrument....!!

Request to kindly help me with some circuit ideas or ICs which can directly convert these pulses to DC Volts...

Regards

I dont wish to use a Microcontroller... (Cos I donno abt it..

Pulses of varying width will be generated from an optocoupler connected to a Wind Speed Sensor... These pulses needs to be converted using a curcuit to a DC Voltage of, say, 0 - 1V... For low speed, the pulse width will be long and for high speed, pulse width will bee short.... I am planning to have some trim pots to finally calibrate the wind sensor using a reference instrument....!!

Request to kindly help me with some circuit ideas or ICs which can directly convert these pulses to DC Volts...

Regards