GeoAVR

Member level 2

- Joined

- Jun 4, 2014

- Messages

- 48

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 6

- Activity points

- 366

Dear all,

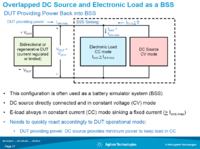

I want to design an equipment that simulates a battery supply system (multiple battery cells connected together for a Vout =20V).

The problem is that I want to implement a Charge and Discharge function with controlled charging and discharging impedance.

Is it possible to do this with a Programmable power supply i.e. from NI using Labview?

Do I also need a programmable power electronic load connected in parallel with power supply?

What design would you recommend?

Thank you in advance.

I want to design an equipment that simulates a battery supply system (multiple battery cells connected together for a Vout =20V).

The problem is that I want to implement a Charge and Discharge function with controlled charging and discharging impedance.

Is it possible to do this with a Programmable power supply i.e. from NI using Labview?

Do I also need a programmable power electronic load connected in parallel with power supply?

What design would you recommend?

Thank you in advance.