Shanmukesh

Newbie level 6

Brief Introduction of the project:

Three phase induction motor overload protection relay using a microcontroller based circuit.

Parameters being Monitored by Microcontroller:

Three phase current consumed by the motor.

Parameters known:

Motor's rated current

Service factor

Locked rotor current of motor

Locked rotor withstand time.

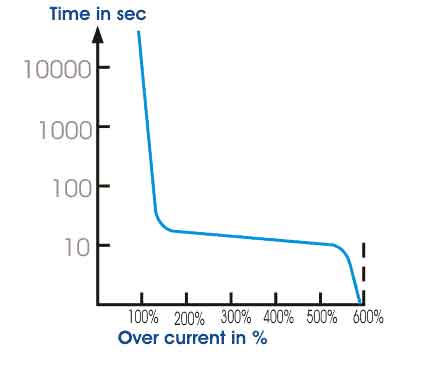

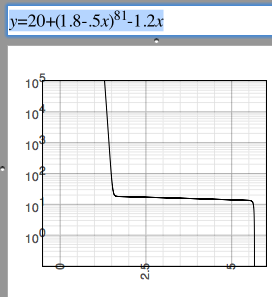

How do I set the Overload curve or response curve of the relay? (Current v/s time)

The probable solution can be, by implementing a lookup table.

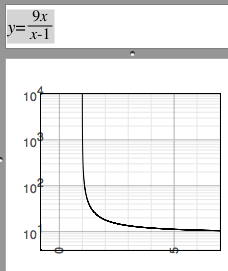

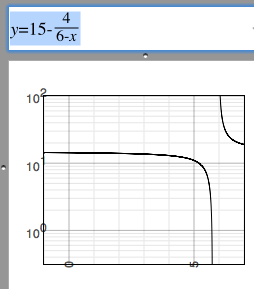

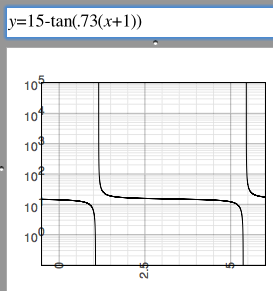

but what would be the Equation of the curve so that it can be calculated in run-time.

Three phase induction motor overload protection relay using a microcontroller based circuit.

Parameters being Monitored by Microcontroller:

Three phase current consumed by the motor.

Parameters known:

Motor's rated current

Service factor

Locked rotor current of motor

Locked rotor withstand time.

How do I set the Overload curve or response curve of the relay? (Current v/s time)

The probable solution can be, by implementing a lookup table.

but what would be the Equation of the curve so that it can be calculated in run-time.