phatcreators

Full Member level 5

What is load cell ? How it works ?

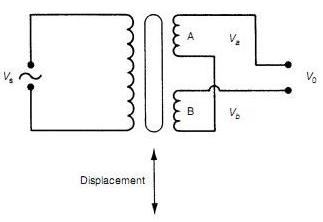

Inside it there are two small (tiny) transformers whose one wire is common to each other and there are two other wires (one for each).

How to test it or check it, whether its working fine or not ?

They are usually connected with a shaft (roller) that rotates and take the packaging film to the rewinding shaft.

thanks

Inside it there are two small (tiny) transformers whose one wire is common to each other and there are two other wires (one for each).

How to test it or check it, whether its working fine or not ?

They are usually connected with a shaft (roller) that rotates and take the packaging film to the rewinding shaft.

thanks