Tahmid

Advanced Member level 6

- Joined

- Jun 17, 2008

- Messages

- 4,756

- Helped

- 1,798

- Reputation

- 3,588

- Reaction score

- 1,656

- Trophy points

- 1,413

- Location

- Berkeley, California

- Activity points

- 30,583

Hi all,

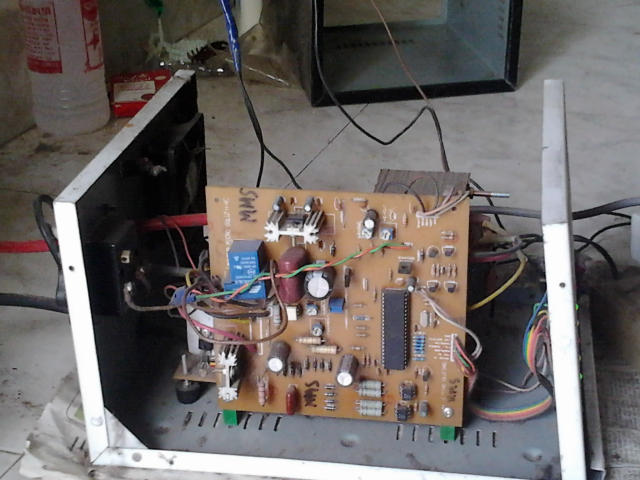

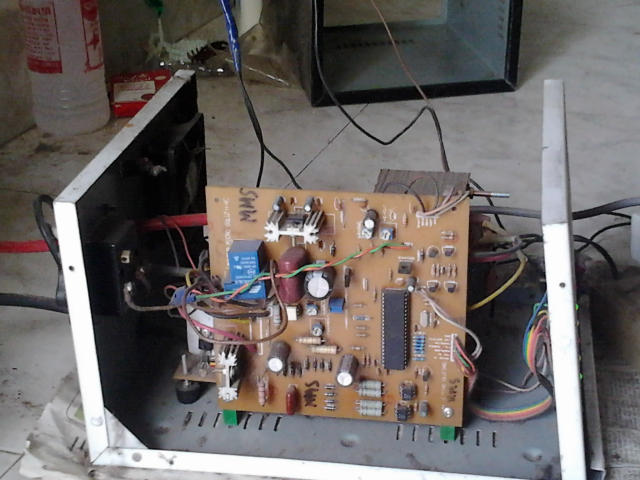

rajudp and sahu wanted to see pics of my inverter that I mentioned earlier in another post, so here it is. For the benefit of the members, I describe the circuit as:

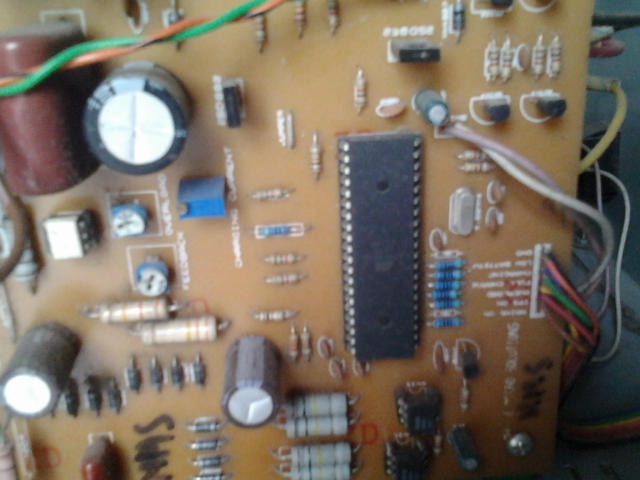

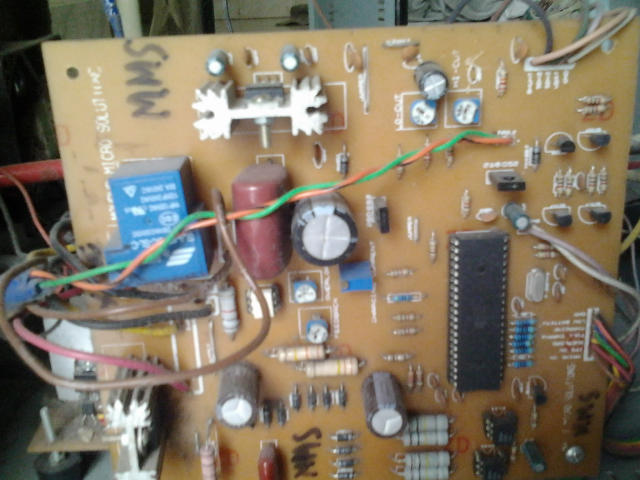

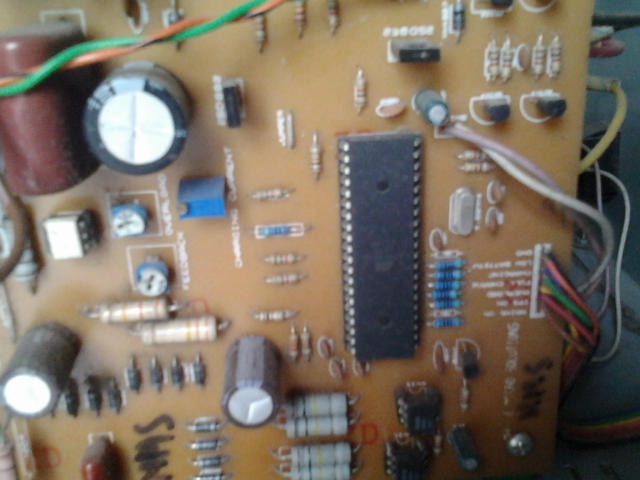

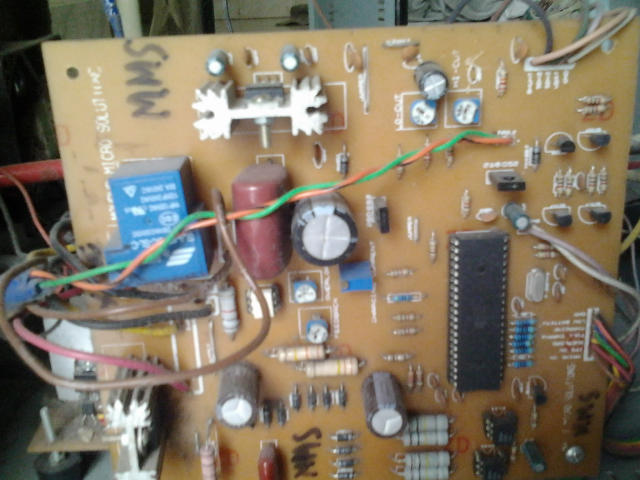

*single microcontroller/controller (ATMEGA16/32)

*no op-amps, only chips are the micro, opto-couplers and regulator (7805)

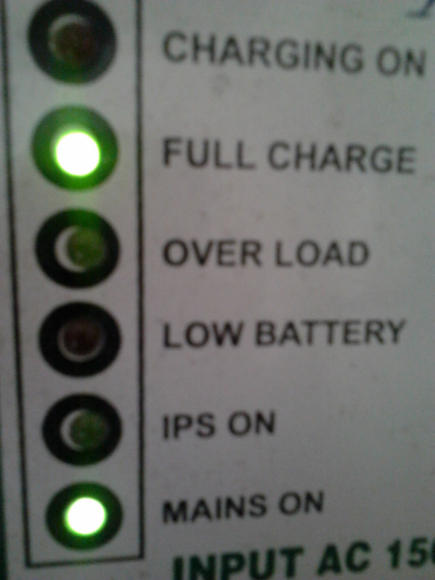

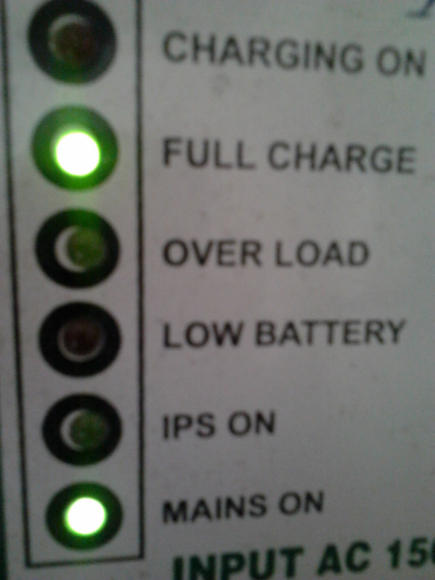

*low-battery/overload/short-circuit protection

*thyristor controlled battery charger, using the MOSFET body diode as the AC-DC rectifier

*charger maintains the battery voltage (top) between 13.2-13.5v (adjustable) to maximize the battery life

*6-LED display

*Only 93 parts in entire control circuit

*Delay between switchover to prevent inrush current

The method used here, described for those who may benefit from it:

-Initialize all ports and peripherals[ADC, Timers, Compare Modules]

-Initialize interrupts for Timer0 and compare module for

-For PWM, use Timer1 and 16-bit Phase and Frequency Correct PWM mode so the PWM runs completely on the hardware level without need for interaction to keep it running

-The AVR senses whether mains is present or not using a standard opto (4N35).

-If mains present, check battery level

-If battery level < 13.5v (this voltage is set using a pot, so can be easily adjusted), charge at the set current(set with a pot)

-If battery level > 13.5v, stop charging

-While battery > 13.2v, stop charging

-If battery voltage drops instantly start charging again

-Triac based, uses Timer0 and compare module with interrupt for phase angle control for fast charge, never overcharges battery, battery hasn't ever heated up till now and 2 year old battery still gives good backup, so charging algorithm is good for battery life

-Check mains

-If mains absent, initialize Timer and start PWM

-Check battery voltage, stop PWM and indicate on LED when battery falls below 10.8v (this is also set with a pot), response time is fast so a short circuit that produces an instant voltage drop is detected

-Check load level, check against preset level (set with pot) and if too high, shut down and indicate

-Check output voltage, adjust as required

-Check mains

*Coding is done with mikroBASIC PRO for AVR

*All voltages mentioned, eg 13.2v, 13.5v, 10.8v, Overload voltage, etc are all adjustable and set with variable resistors

I will upload the schematic and PCB design soon.

Tahmid.

rajudp and sahu wanted to see pics of my inverter that I mentioned earlier in another post, so here it is. For the benefit of the members, I describe the circuit as:

*single microcontroller/controller (ATMEGA16/32)

*no op-amps, only chips are the micro, opto-couplers and regulator (7805)

*low-battery/overload/short-circuit protection

*thyristor controlled battery charger, using the MOSFET body diode as the AC-DC rectifier

*charger maintains the battery voltage (top) between 13.2-13.5v (adjustable) to maximize the battery life

*6-LED display

*Only 93 parts in entire control circuit

*Delay between switchover to prevent inrush current

The method used here, described for those who may benefit from it:

-Initialize all ports and peripherals[ADC, Timers, Compare Modules]

-Initialize interrupts for Timer0 and compare module for

-For PWM, use Timer1 and 16-bit Phase and Frequency Correct PWM mode so the PWM runs completely on the hardware level without need for interaction to keep it running

-The AVR senses whether mains is present or not using a standard opto (4N35).

-If mains present, check battery level

-If battery level < 13.5v (this voltage is set using a pot, so can be easily adjusted), charge at the set current(set with a pot)

-If battery level > 13.5v, stop charging

-While battery > 13.2v, stop charging

-If battery voltage drops instantly start charging again

-Triac based, uses Timer0 and compare module with interrupt for phase angle control for fast charge, never overcharges battery, battery hasn't ever heated up till now and 2 year old battery still gives good backup, so charging algorithm is good for battery life

-Check mains

-If mains absent, initialize Timer and start PWM

-Check battery voltage, stop PWM and indicate on LED when battery falls below 10.8v (this is also set with a pot), response time is fast so a short circuit that produces an instant voltage drop is detected

-Check load level, check against preset level (set with pot) and if too high, shut down and indicate

-Check output voltage, adjust as required

-Check mains

*Coding is done with mikroBASIC PRO for AVR

*All voltages mentioned, eg 13.2v, 13.5v, 10.8v, Overload voltage, etc are all adjustable and set with variable resistors

I will upload the schematic and PCB design soon.

Tahmid.

Last edited: