R

red_alert

Guest

Hello,

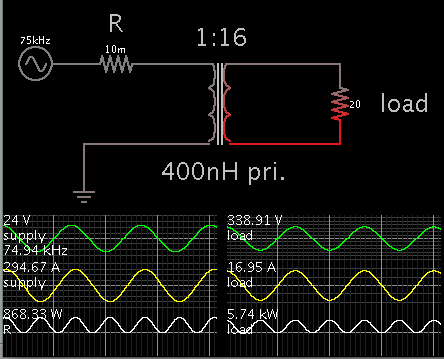

I need to design a ferrite transformer for a 4kW DC-DC full bridge converter (24V -> 350V). I'm going to use ETD59 (if it could handle 4kW) or E71 ferrite core (3C90), working at 75-100kHz.

After many calculations, using some software tools or designing formulas, seems like the primary inductor should have 1 (one) turn of very thick (litz) wire.

How to practically make it? I think I'll have to "spread" it across the entire ferrite core.. or should I have one single (thick) wire in the middle?

Do you know a feasible way to do this? How to better interleave the primary and secondary inductors?

Thanks in advance for any support.

I need to design a ferrite transformer for a 4kW DC-DC full bridge converter (24V -> 350V). I'm going to use ETD59 (if it could handle 4kW) or E71 ferrite core (3C90), working at 75-100kHz.

After many calculations, using some software tools or designing formulas, seems like the primary inductor should have 1 (one) turn of very thick (litz) wire.

How to practically make it? I think I'll have to "spread" it across the entire ferrite core.. or should I have one single (thick) wire in the middle?

Do you know a feasible way to do this? How to better interleave the primary and secondary inductors?

Thanks in advance for any support.