copilu

Newbie level 4

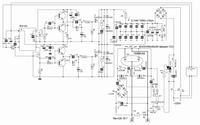

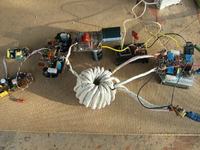

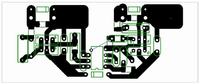

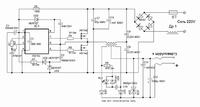

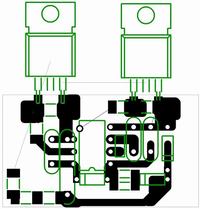

welder schematics

i really don`n know. i have the document "as it is"

ibersoy2006 said:i need switdh mode arc welder machine use microcontroller type number and datasheet

Added after 4 minutes:

i need to invertor sudura.pdf of the use microcontroller type number it did not write shematic diagram you give microcontoller type number i be very happy

thanks

i really don`n know. i have the document "as it is"