c_mitra

Advanced Member level 6

Re: Commutation table using Hall sensors

Right but Hall sensor outputs depend on the speed and the rotational speed depends on the applied power line frequency...

The Hall sensor output is the only way to actually ensure that the rotor is actually spinning as per the applied frequency. You slowly increase the frequency and ensure that the rotor is actually speeding up by looking at the Hall sensors.

Your approach is correct but you should try to sync with the transitions and not with the levels.

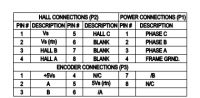

As i first step i will read the hall sensor values and just switch the legs.

Right but Hall sensor outputs depend on the speed and the rotational speed depends on the applied power line frequency...

The Hall sensor output is the only way to actually ensure that the rotor is actually spinning as per the applied frequency. You slowly increase the frequency and ensure that the rotor is actually speeding up by looking at the Hall sensors.

Your approach is correct but you should try to sync with the transitions and not with the levels.