kam1787

Advanced Member level 3

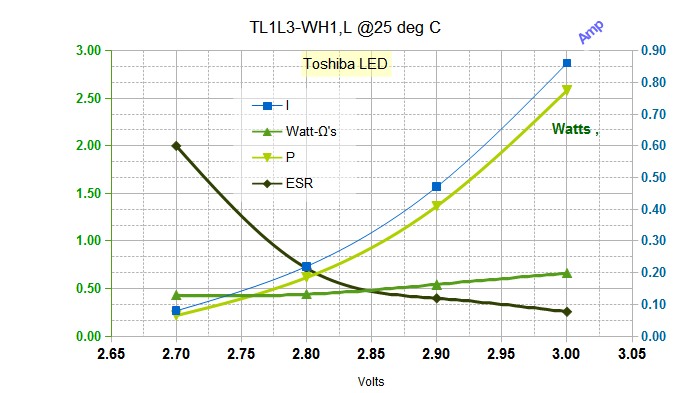

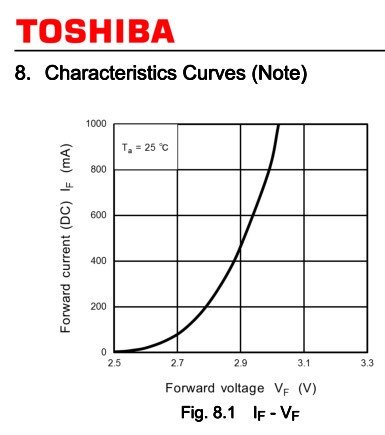

White or Blue high bright (HB) LEDs have a threshold is near 2.5 but ESR linear asymptote is around 2.85 and actual Vf forward voltage depends on W capacity * ESR of LED

.

There was another forum where you trying to explain the ESR concept. Sadly I lost the thread. I still have absolutely no clue as to a LED's "ESR" relevance or use in practical electronics.

The second part of your statement [that I bolded] is....................unusual. Care to elaborate?