T

treez

Guest

Hello

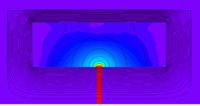

I have just calculated that a 1.25mm gap in the centre post (only) of the following core......PQ50/50-3C96

...will give an inductance of 341uH with 33 turns, and the saturation current will be 9A7.

(considering 0.3T = saturation)

However, i used the Effective core area (Ae) in the calculation and not the minimum core area (Amin).

...Is this correct, or do i need to use the area of just the centre post, where the gap will be?

PQ50/50-3C96 datasheet:

https://www.ferroxcube.com/prod/assets/pq5050.pdf

I do this by calculating reluctance via Rel = length/(u0.ur.A), then L = N^2/Reluctance

...i calculate reluctance of ferrite and gap then add them ....but which Area value gets used for core and air gap?

I have just calculated that a 1.25mm gap in the centre post (only) of the following core......PQ50/50-3C96

...will give an inductance of 341uH with 33 turns, and the saturation current will be 9A7.

(considering 0.3T = saturation)

However, i used the Effective core area (Ae) in the calculation and not the minimum core area (Amin).

...Is this correct, or do i need to use the area of just the centre post, where the gap will be?

PQ50/50-3C96 datasheet:

https://www.ferroxcube.com/prod/assets/pq5050.pdf

I do this by calculating reluctance via Rel = length/(u0.ur.A), then L = N^2/Reluctance

...i calculate reluctance of ferrite and gap then add them ....but which Area value gets used for core and air gap?

Last edited by a moderator: