Vermes

Advanced Member level 4

Powered butt is ZD-929 IRON. A transformer was from a video on a single secondary winding 25V/2A. From this transformer, two taps were taken of 23V to power the heater and about 8V to power the electronics +5V, the second winding was added about 8V to obtain the voltage -5V. Two independent low voltage windings were received then. They powered modified a modified power supply using the stabilizers.

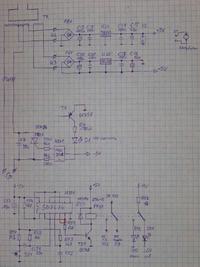

The basic scheme was modified:

- instead of the relay feeding power to the heater, a triac with optotriac was used (added components have digital index 4X)

- a relay switching the temperature display from butt on the indication of the potentiometer setting slider (added components have index 5X)

- index of the rest of components on scheme from PE 3/99 weren't changed, on ly in the power supply changed/added components were highlighted with ' mark

The relay is switchable by one button via flip-D contained in SN7474.

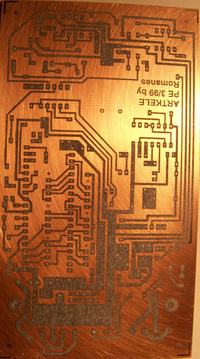

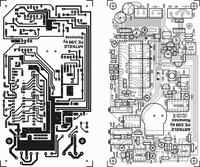

The whole was placed in a computer power supply housing. A board (thermal transfer) was designed, on which the whole electronics are: a controller system, mili-voltmeter and relay control. Signaling elements (displays and LEDs) and the button are soldered from the paths side. Seven-segments displays have an unusual arrangement of pins, to reduce power consumption, they are powered by reduced voltage through three 1N4001 diodes connected in series.

Most of components were taken from disassembly/stocks.

While regulating the station, only values of the resistors: R4 to 10kΩ, R6 increased the additional 52kΩ (P2 of value 10kΩ). Ventilator was powered 5V – it works very quietly, common heat sink US4 and TK1 is warm while working with a maximum tip temperature.

Link to original thread – Stacja lutownicza z PE 3/99 by Romanes

Last edited: