Azaruk

Member level 1

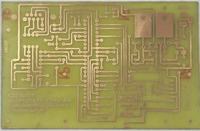

pcb photo transfer press and peal

This has been an interesting thread to read, but I STILL maintain that the photo technique using Positiv 20 has been the best method for me. I always get consistent results, with excellent track definition.

Exposure seems to be the major criterion, with developer strength running a close second. Once these two issues have been resolved, the results are excellent.

I would not consider trying any other method.

This has been an interesting thread to read, but I STILL maintain that the photo technique using Positiv 20 has been the best method for me. I always get consistent results, with excellent track definition.

Exposure seems to be the major criterion, with developer strength running a close second. Once these two issues have been resolved, the results are excellent.

I would not consider trying any other method.