skarkowtsky

Advanced Member level 4

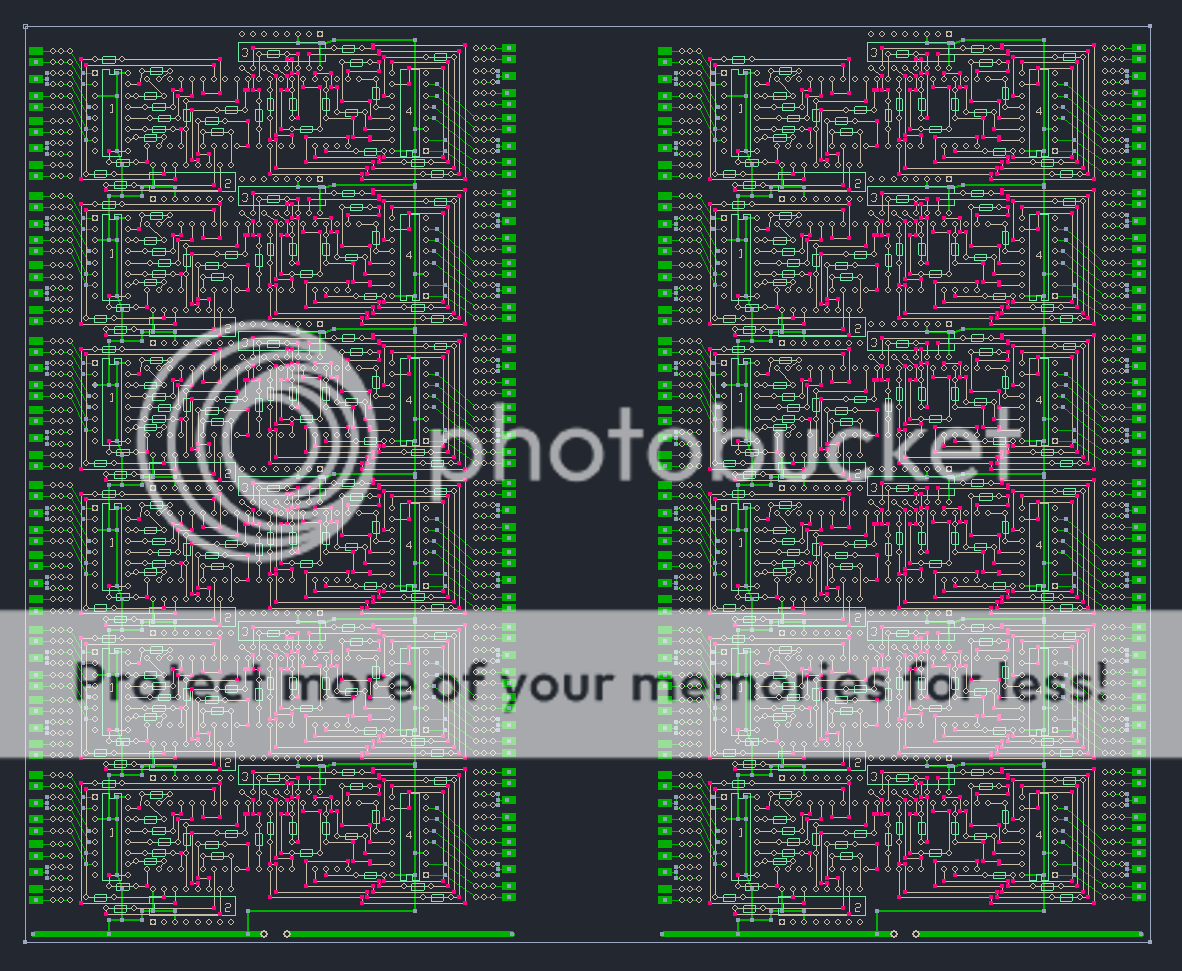

I have Express PCB. It's easier for me to do preliminary sketches in Illustrator. I will recreate it in Express PCB today.

As for the other 8 pins of the 4511s, they will be connected by wire from beneath the board, no traces, to save space in the case. I think this is going to work. If it doesn't, the entire case has to be hand wired.

I've since created the right side circuit, too!

I'm also wondering I could use the chemicals and make my own board. I do have a Dremel press, but still, it's a lot of holes to drill!!

As for the other 8 pins of the 4511s, they will be connected by wire from beneath the board, no traces, to save space in the case. I think this is going to work. If it doesn't, the entire case has to be hand wired.

I've since created the right side circuit, too!

I'm also wondering I could use the chemicals and make my own board. I do have a Dremel press, but still, it's a lot of holes to drill!!