wfg42438

Member level 3

- Joined

- Jun 29, 2015

- Messages

- 54

- Helped

- 0

- Reputation

- 0

- Reaction score

- 0

- Trophy points

- 6

- Location

- California

- Activity points

- 620

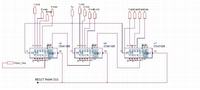

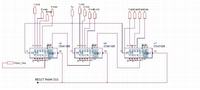

Hello I am attempting to set up three cascaded counters each going to BCD decoders and then to seven segment displays. i have one low frequency clock being applied to the clock up signal which i am attempting to count. An additional clock is also being used for the reset line of all counters. Please note that the input clock is a low frequency signal of approximately 1-35 Hz, and i wish to have the other clock reset the counter every 28.8 seconds so this clock has a frequency of 34.72mhz.

Please note that for now the clock signals have been given logic high levels of 5V and a logic low of 0V

You might be wondering why i want to set up such a slow and odd counter well this is for a project iam working on which is well described in this thread: https://www.edaboard.com/threads/353222/#post1512642

A much better solution has already been proposed but i am really curios to see how this counter works before i attempt the proper solution in the thread above.

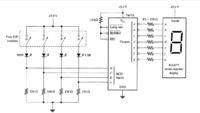

Now for the counters i wish to use the count up function therefore i have held Enable, and count down high by applying VDD (5V) as specified in the data sheet

For the decoders i was not too sure about the connection scheme so i looked over an old digital logic lab book and saw the connection scheme attached. Please note i have used the 330 ohm resistors at the output of the decoder and the 1k resistor with one end to VDD and the other tied to LT, BI/RBO & RBI

Attached is also a sketch of the connections i have made for the counter please note that this sketch shows the connections for a single set of counter and decoders . I have also shown a connection scheme for the cascaded counters in an additional image

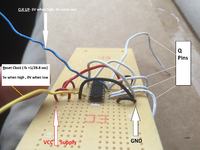

As of now i have built and tested the circuit however the counters don't seem to work properly, when checking them i don't see it counting when probing the Q outputs using an oscilloscope, i only see noise.

I then built a single counter and decoder to see if maybe something was connected improperly and here i periodically saw a count when using the scope however it was not very clean (Image attached) . Even then the however the decoders did not output anything. When probing the a-g pins on the decoder with a voltmeter i saw the decoder was sending nothing to the 7 segment displays as the voltmeter always read 0V across those pins

Please let me know if any of the connections shown are incorrect i would really appreciate the feedback! I am sure there is something i am forgetting to do which is why the set up is giving me nothing, thank you in advance!

Link to Data Sheets:

https://www.mouser.com/ds/2/405/cd4511b-452627.pdf

https://www.mouser.com/ds/2/405/cd40192b-439702.pdf

Please note that for now the clock signals have been given logic high levels of 5V and a logic low of 0V

You might be wondering why i want to set up such a slow and odd counter well this is for a project iam working on which is well described in this thread: https://www.edaboard.com/threads/353222/#post1512642

A much better solution has already been proposed but i am really curios to see how this counter works before i attempt the proper solution in the thread above.

Now for the counters i wish to use the count up function therefore i have held Enable, and count down high by applying VDD (5V) as specified in the data sheet

For the decoders i was not too sure about the connection scheme so i looked over an old digital logic lab book and saw the connection scheme attached. Please note i have used the 330 ohm resistors at the output of the decoder and the 1k resistor with one end to VDD and the other tied to LT, BI/RBO & RBI

Attached is also a sketch of the connections i have made for the counter please note that this sketch shows the connections for a single set of counter and decoders . I have also shown a connection scheme for the cascaded counters in an additional image

As of now i have built and tested the circuit however the counters don't seem to work properly, when checking them i don't see it counting when probing the Q outputs using an oscilloscope, i only see noise.

I then built a single counter and decoder to see if maybe something was connected improperly and here i periodically saw a count when using the scope however it was not very clean (Image attached) . Even then the however the decoders did not output anything. When probing the a-g pins on the decoder with a voltmeter i saw the decoder was sending nothing to the 7 segment displays as the voltmeter always read 0V across those pins

Please let me know if any of the connections shown are incorrect i would really appreciate the feedback! I am sure there is something i am forgetting to do which is why the set up is giving me nothing, thank you in advance!

Link to Data Sheets:

https://www.mouser.com/ds/2/405/cd4511b-452627.pdf

https://www.mouser.com/ds/2/405/cd40192b-439702.pdf