bmandl

Full Member level 4

Hello,

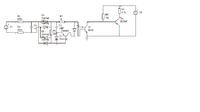

I am on my new school project - aquarium controling device. I will be measuring ph of water with temperature compensation and I will regulate water temperature with pwm on microcontroller. Here comes the problem of me, not knowing much about triacs.

I newer worked with pwm before and I don't have basic idea, how this is done. Are there any specific calculations which must be considered before controlling triac with pwm? Does it mean, that if I put out 50% duty cycle from microcontroller, that triac will also provide 50% of power from mains to the heater? What else do I need to consider for this kind of regulation? How do I involve temperature to duty cycle - do I make it experimental (changing duty cycle, until temperature stabilize) or must be some kind of calculation made to exactly determine duty cycle for desired temperature?

This will be enough questions for now, I appreciate any answers.

I am on my new school project - aquarium controling device. I will be measuring ph of water with temperature compensation and I will regulate water temperature with pwm on microcontroller. Here comes the problem of me, not knowing much about triacs.

I newer worked with pwm before and I don't have basic idea, how this is done. Are there any specific calculations which must be considered before controlling triac with pwm? Does it mean, that if I put out 50% duty cycle from microcontroller, that triac will also provide 50% of power from mains to the heater? What else do I need to consider for this kind of regulation? How do I involve temperature to duty cycle - do I make it experimental (changing duty cycle, until temperature stabilize) or must be some kind of calculation made to exactly determine duty cycle for desired temperature?

This will be enough questions for now, I appreciate any answers.