aliman8

Junior Member level 1

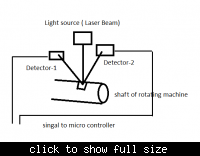

Hi i have come acorss a problem in which i need to measure revolutions per second (rate ) and direction of spin in such a way that main shaft is static and only bearings across it is moving.Now i can not use potentiometer for the measurement because shaft is static so i am thinking about the shaft optical encoder ?? Any one having better idea can please guide me

Ali

Ali