themaccabee

Full Member level 4

Hi,

May be this is silly .. But i ve a doubt here ..

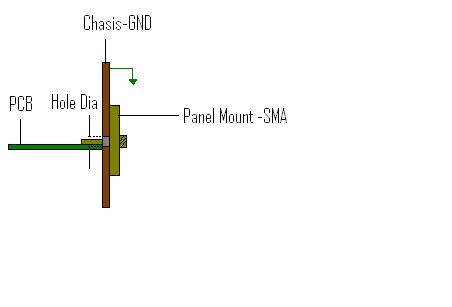

I need to mount a Panel Mount SMA connector to a chasis, then solder the conductor to a PCB trace.(800MHz)

My doubt is that is there any requirement that needs to be met for the drilling hole that should be put on the chasis for the connector signal conductor to pass through??

Wat exactly decides the minimum or maximum hole diameter??And which performance parameters(like return loss..) can go wrong if we made the diameter smaller but Of course not touching the conductor.. or made higher..??

or made higher..??

May be this is silly .. But i ve a doubt here ..

I need to mount a Panel Mount SMA connector to a chasis, then solder the conductor to a PCB trace.(800MHz)

My doubt is that is there any requirement that needs to be met for the drilling hole that should be put on the chasis for the connector signal conductor to pass through??

Wat exactly decides the minimum or maximum hole diameter??And which performance parameters(like return loss..) can go wrong if we made the diameter smaller but Of course not touching the conductor..