jerrypoo

Newbie level 4

Hello all!

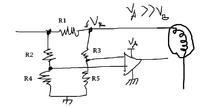

I try to build a simple system that cuts off the power from an electric motor (small, DC motor) when there is too much resistance/work/friction ...

I guss the idea is to put a small resistor and that way measure the electric current. The best would be to use a relay, that would fit some other things, too.

But ... I'm really not good designing anything so all help are welcome! I understand the idea behind this but I need help with the basic design. As simple as possible.

Any idea or design for a simple system?

Thanks in advance, all ideas welcome!

I try to build a simple system that cuts off the power from an electric motor (small, DC motor) when there is too much resistance/work/friction ...

I guss the idea is to put a small resistor and that way measure the electric current. The best would be to use a relay, that would fit some other things, too.

But ... I'm really not good designing anything so all help are welcome! I understand the idea behind this but I need help with the basic design. As simple as possible.

Any idea or design for a simple system?

Thanks in advance, all ideas welcome!