powersys

Advanced Member level 1

Hi...

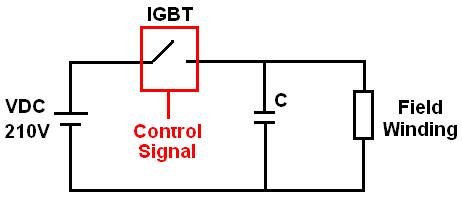

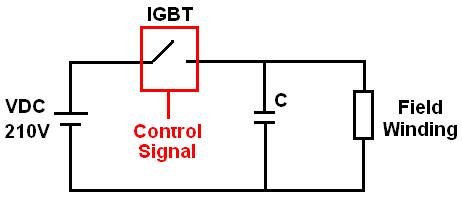

I wish to control the speed (close-loop control with speed feedback) of a dc motor via PWM field winding voltage control (see attached figure). Do I need any diode in the circuit? Is the voltage seen at the terminals of field winding "ripple free"? Is the current flowing through the field winding "ripple free"?

Thanks.

I wish to control the speed (close-loop control with speed feedback) of a dc motor via PWM field winding voltage control (see attached figure). Do I need any diode in the circuit? Is the voltage seen at the terminals of field winding "ripple free"? Is the current flowing through the field winding "ripple free"?

Thanks.