delwin

Newbie level 6

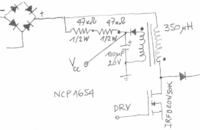

According to the datasheet, the NCP1654 from ON Semniconductors, should be powered by an external power supply +12V to about +20VDC max.

In the application note, they use a +15VDC, but the question is, how powerfull should the external PSU be?

The on-chip driver is capable of delivering +-1,5A and on the schematic of the chip, the Vcc goes directly to the DRV buffer +rail, so I suppose the power supply should be atleast 1,5A@15V, is this correct?

The question is because the datasheet does mention only the chip power consumption but not the load consumption.

Any suggestions about the 15V@2A PSU?

In the application note, they use a +15VDC, but the question is, how powerfull should the external PSU be?

The on-chip driver is capable of delivering +-1,5A and on the schematic of the chip, the Vcc goes directly to the DRV buffer +rail, so I suppose the power supply should be atleast 1,5A@15V, is this correct?

The question is because the datasheet does mention only the chip power consumption but not the load consumption.

Any suggestions about the 15V@2A PSU?