pasicr

Advanced Member level 1

10mm red led drive

Hi for all,

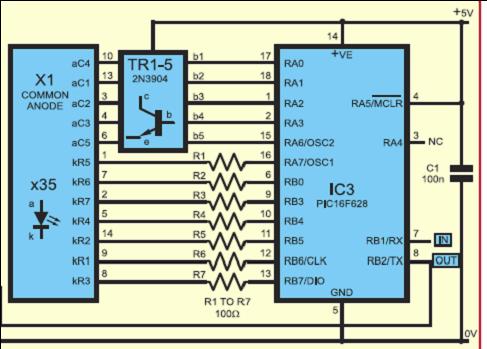

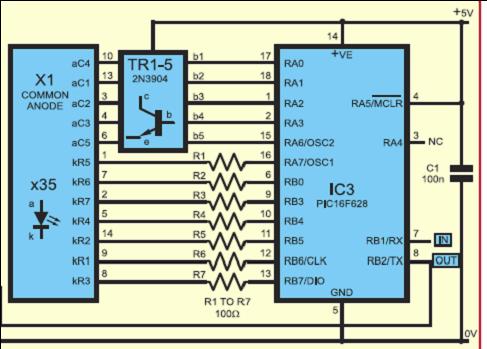

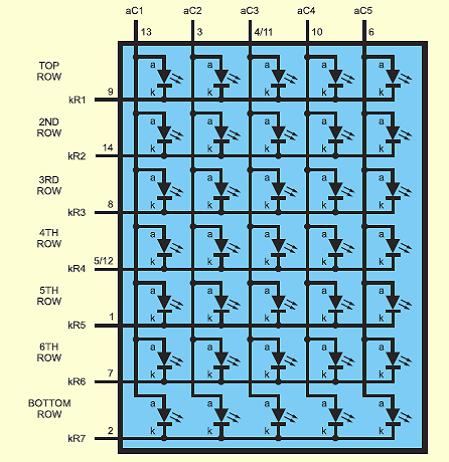

I use led driver (picture 1)

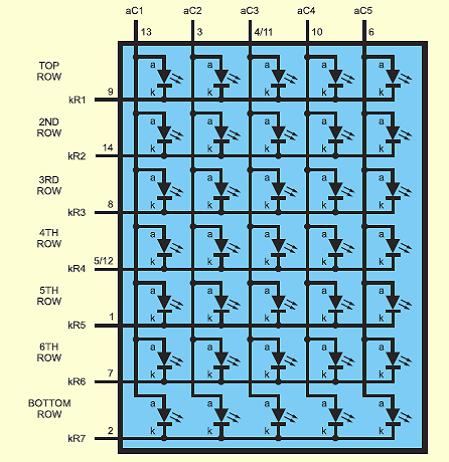

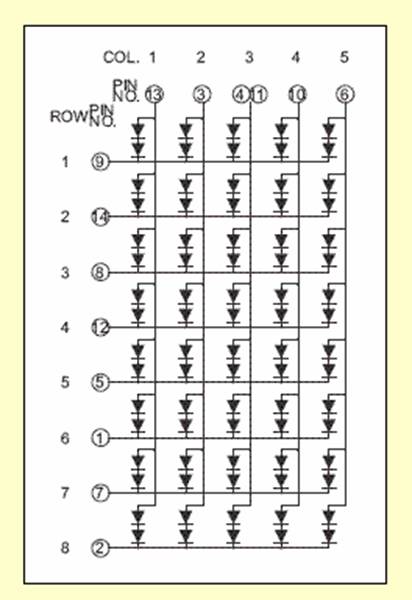

for drive led matrix 5x7 (one led is 5mm, picture 2).

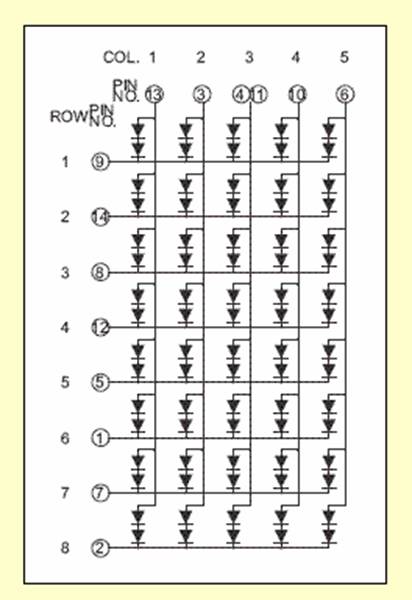

Now I buy led matrix but larger with 2x5mm led (5x7, picture 3).

With old led driver, new led display with 10mm led give weak brightness,

I like to hear opinion from everibody, how to change old led driver, with minimum modification, to get maximum from new led matrix,

(for example increase voltage on chatode on 2N3904?...),

regards

p.s. new led display is 5x8, is not a problem, I not use bottom row

Hi for all,

I use led driver (picture 1)

for drive led matrix 5x7 (one led is 5mm, picture 2).

Now I buy led matrix but larger with 2x5mm led (5x7, picture 3).

With old led driver, new led display with 10mm led give weak brightness,

I like to hear opinion from everibody, how to change old led driver, with minimum modification, to get maximum from new led matrix,

(for example increase voltage on chatode on 2N3904?...),

regards

p.s. new led display is 5x8, is not a problem, I not use bottom row