sabu31

Advanced Member level 1

Hi all,

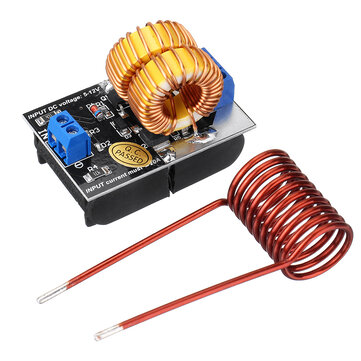

I wanted to know about the resonant inductor design with DC input from low voltage (say 24V to 36V) for 1kW induction heating system. Since the current is higher as compared to a high voltage system, will the inductance required and hence number of turns reduce as compared to a high voltage induction system.

Thanks

I wanted to know about the resonant inductor design with DC input from low voltage (say 24V to 36V) for 1kW induction heating system. Since the current is higher as compared to a high voltage system, will the inductance required and hence number of turns reduce as compared to a high voltage induction system.

Thanks