4tuty

Member level 3

I am going to use FGA21 InGaAs photodiode from thorlabs. I want to know which one of the circuit is better for me (PFA). my application is not for high speed application but i need low noise, linear and precise application.

I saw some tutorial photovoltaic mode is best but from the spec sheet of FGA21 it needs reverse bias of 3V max. so i have used 2.8 V bias for photodiode see figure 2.

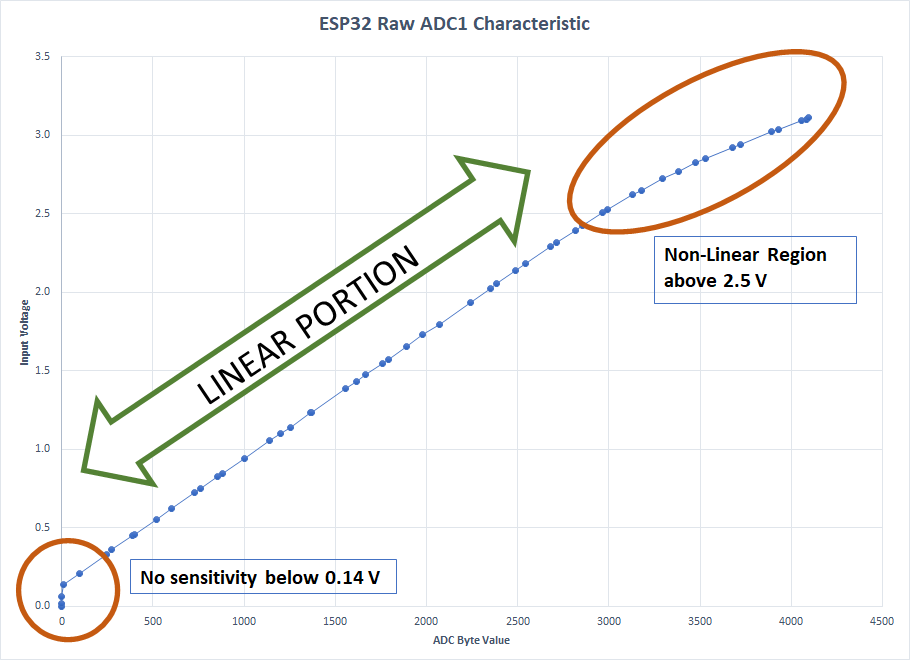

I have used transimpedance amplifier OPA380 for both modes and give the output voltage to ESP 32 A0 pin(not shown). advice needed

I saw some tutorial photovoltaic mode is best but from the spec sheet of FGA21 it needs reverse bias of 3V max. so i have used 2.8 V bias for photodiode see figure 2.

I have used transimpedance amplifier OPA380 for both modes and give the output voltage to ESP 32 A0 pin(not shown). advice needed