FSR

Newbie level 1

Hi there, my name is Neil, and i have a question for all willing to help

FSR stands for "Focus sport rally" I am currently in the process of building up a 2002 ford focus zx3 into a rally car.

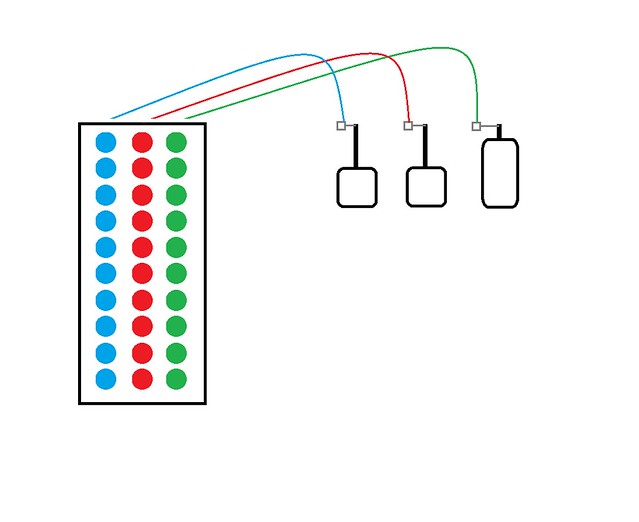

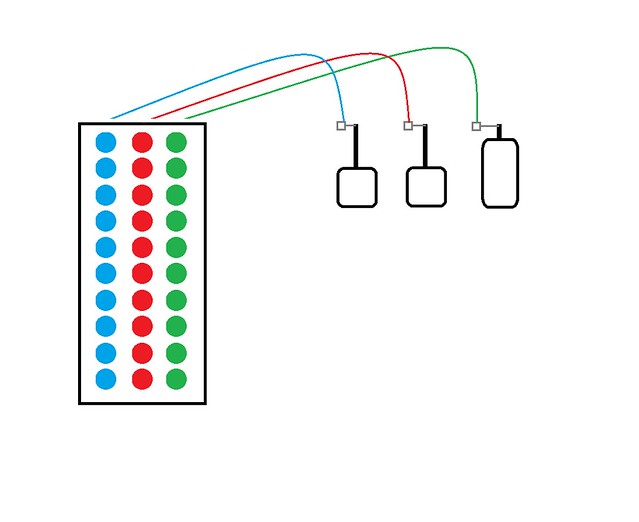

what I'm looking to do, is build a circuit which will allow me to have three rows of ten LEDs to sequentially light up with the movement of the clutch,brake, and the accelerator

such as...

I would like it so that if the accelerator is full throttle all ten green LEDS will be lit, if its half only five will be lit and so on.. that would be the same for the clutch and brake now i have done some circuitry in school as well as just some hobby stuff, but I feel I'm either over thinking this or I am out of my league.

I have toyed with using servos to move a conductor over open contacts connected to the leds, however i feel this would not be responsive enough for my overall objective.

any help would be greatly appreciated

thanks

Neil

FSR stands for "Focus sport rally" I am currently in the process of building up a 2002 ford focus zx3 into a rally car.

what I'm looking to do, is build a circuit which will allow me to have three rows of ten LEDs to sequentially light up with the movement of the clutch,brake, and the accelerator

such as...

I would like it so that if the accelerator is full throttle all ten green LEDS will be lit, if its half only five will be lit and so on.. that would be the same for the clutch and brake now i have done some circuitry in school as well as just some hobby stuff, but I feel I'm either over thinking this or I am out of my league.

I have toyed with using servos to move a conductor over open contacts connected to the leds, however i feel this would not be responsive enough for my overall objective.

any help would be greatly appreciated

thanks

Neil