wan65

Newbie level 6

Hello

I want to use this service:

https://support.seeedstudio.com/knowledgebase/articles/388503-what-are-the-pcb-panelization-rules

but I don't fully understand what do they mean with their requirements...

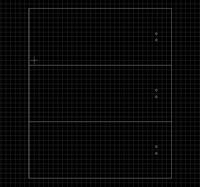

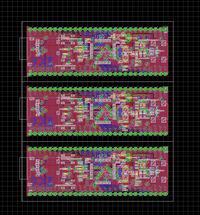

So far I've done this:

I have the same board 3 times, but what do they mean by "V-cuts on 20 layer"? The 20 layer is board outline:

Is this okay?

Also, which JOB script for eagle should I use to export the gerbers for seeedstudio?

I want to use this service:

https://support.seeedstudio.com/knowledgebase/articles/388503-what-are-the-pcb-panelization-rules

but I don't fully understand what do they mean with their requirements...

So far I've done this:

I have the same board 3 times, but what do they mean by "V-cuts on 20 layer"? The 20 layer is board outline:

Is this okay?

Also, which JOB script for eagle should I use to export the gerbers for seeedstudio?