I14R10

Full Member level 3

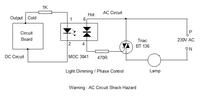

I built this thing

[at dmohankumar .files .wordpress .com /2016 /04 /moc -3041 -circuit .jpg]

except I control the heater at 12V AC and the input to opto-coupler is from atmega8.

And I use 8kHz PWM signal to opto-coupler MOC 3041 to control the power. It seems to be working, but how?

There are around 133 pulses of PWM signal in one period of the AC sine wave signal. It should always be at near 100% on. Because the triac would be turned on very soon after the sine wave crosses zero.

I can explain it if the opto-coupler is turning on the triac according to brightness of the LED from input. That would make sense. If the PWM has 50% duty cycle, the LED within opto coupler would glow at 50% power and the opto coupler would fire triac when sine wave phase is at 90 degrees.

Another explanation is that opto coupler fires only at zero crossing and sometimes the PWM signal happens to be at 0 and sometimes at 1 when zero crossing happens.

[at dmohankumar .files .wordpress .com /2016 /04 /moc -3041 -circuit .jpg]

except I control the heater at 12V AC and the input to opto-coupler is from atmega8.

And I use 8kHz PWM signal to opto-coupler MOC 3041 to control the power. It seems to be working, but how?

There are around 133 pulses of PWM signal in one period of the AC sine wave signal. It should always be at near 100% on. Because the triac would be turned on very soon after the sine wave crosses zero.

I can explain it if the opto-coupler is turning on the triac according to brightness of the LED from input. That would make sense. If the PWM has 50% duty cycle, the LED within opto coupler would glow at 50% power and the opto coupler would fire triac when sine wave phase is at 90 degrees.

Another explanation is that opto coupler fires only at zero crossing and sometimes the PWM signal happens to be at 0 and sometimes at 1 when zero crossing happens.

Last edited: