Mikezz

Newbie

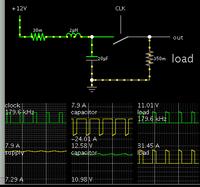

Hey guys, I am currently building a battery powered flyback transformer that uses an ne555 timing chip at 180KHz. The peak current i have worked out will be 29.6A on the primary side of the flyback with the average current being 7.4A.

My question is if I use a battery meant for quad copters with 2200mAh and a discharge rate of 8c (max current of 17.6A) can it handle the peak currents of 29.6A at 180KHz? I have read that at high frequencies above 1KHz that batteries act differently and can draw more current than their maximum discharge rate shown without damage but im just not sure about 29.6A compared to the maximum of 17.6A. Or does all this not matter and i just need to go off of the average current for this circuit and not worry about peak current?

If anyone could tell me if this battery would work or not that would be really helpful, thanks.

My question is if I use a battery meant for quad copters with 2200mAh and a discharge rate of 8c (max current of 17.6A) can it handle the peak currents of 29.6A at 180KHz? I have read that at high frequencies above 1KHz that batteries act differently and can draw more current than their maximum discharge rate shown without damage but im just not sure about 29.6A compared to the maximum of 17.6A. Or does all this not matter and i just need to go off of the average current for this circuit and not worry about peak current?

If anyone could tell me if this battery would work or not that would be really helpful, thanks.