T

treez

Guest

We have five 220uF, 400V electrolytic capacitors in parallel (Nichicon UVR2G222M).

UVR2G222M capacitor datasheet:

http://nichicon-us.com/english/products/pdfs/e-vr.pdf

They are being used in a capacitor discharge unit which acts as a LED flasher.

This capacitor bank is charged up to 333V, and then, every second, they are discharged with a 1 Amp discharge current for 0.3 seconds, then during the proceeding 0.7 seconds they are charged back up to 333V with a 429mA charge current. This happens repeatedly.

thus the frequency of the ripple current in each of these capacitors is very low, (1 Hertz)

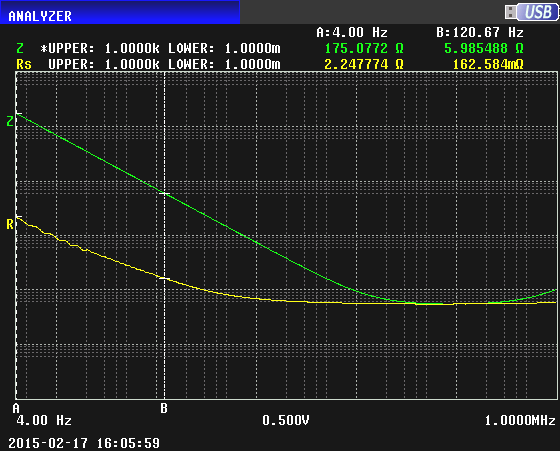

The tan(delta) for these capacitors is 0.25. Therefore, the ESR is tan(delta) * Xc = 36.2 Ohms. (overall ESR for the five capacitors in parallel)

This seems a very high ESR. Surely the ESR cannot be this large?

UVR2G222M capacitor datasheet:

http://nichicon-us.com/english/products/pdfs/e-vr.pdf

They are being used in a capacitor discharge unit which acts as a LED flasher.

This capacitor bank is charged up to 333V, and then, every second, they are discharged with a 1 Amp discharge current for 0.3 seconds, then during the proceeding 0.7 seconds they are charged back up to 333V with a 429mA charge current. This happens repeatedly.

thus the frequency of the ripple current in each of these capacitors is very low, (1 Hertz)

The tan(delta) for these capacitors is 0.25. Therefore, the ESR is tan(delta) * Xc = 36.2 Ohms. (overall ESR for the five capacitors in parallel)

This seems a very high ESR. Surely the ESR cannot be this large?