kripacharya

Banned

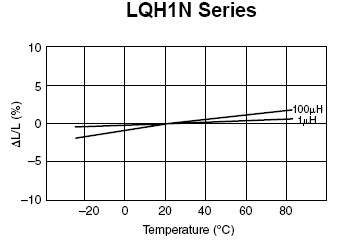

Inductor spec sheets have tolerance and temperature range, but I almost never see a temperature coefficient.

Does the combination of tolerance spec + temp range ~ imply Temp Coeff?

How do i determine temp coeff before procuring the parts.

I also see that capacitors are available as NTC and PTC - possibly to offset a change in L is some LC resonator. So why don't the L's also specify it ?

Does the combination of tolerance spec + temp range ~ imply Temp Coeff?

How do i determine temp coeff before procuring the parts.

I also see that capacitors are available as NTC and PTC - possibly to offset a change in L is some LC resonator. So why don't the L's also specify it ?