mrinalmani

Advanced Member level 1

- Joined

- Oct 7, 2011

- Messages

- 463

- Helped

- 60

- Reputation

- 121

- Reaction score

- 58

- Trophy points

- 1,318

- Location

- Delhi, India

- Activity points

- 5,285

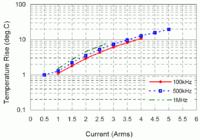

What is the ripple current capability of ceramic capacitors?

I am aware that there is no such limit imposed by the material of the capacitor itself (unlike electrolytic capacitors)

The limit depends solely on the temperature rise, which in turn would depend on the package size of the capacitor.

Even an approximate figure would be greatly appreciated.

Thank you

I am aware that there is no such limit imposed by the material of the capacitor itself (unlike electrolytic capacitors)

The limit depends solely on the temperature rise, which in turn would depend on the package size of the capacitor.

Even an approximate figure would be greatly appreciated.

Thank you