doors666

Junior Member level 1

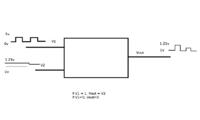

I have a analog dc signal for which the voltage varies from 0-1.23v. I also have a 3.3v pwm signal, for which the worst case frequency will be 1mhz. I need to merge these two so that the output signal is switched as per the pwm but the voltage level is as per the analog signal, kinda like a switched varying dc signal. Too much of voltage should not be dropped in the process and the fast response time is also important. How do I do this.