Electro nS

Full Member level 6

dear guys i am running BIG DC motor from a relay

the relay is acting weirdly after some uses , it gets stuck and needs to be switched on and off several times to run again . some times i hit the relay in order to work !! i have 2 theories for this problem : 1- relay is bad quality (chinease ) and is losing most of its life while soldering it at high temperature to the PCB !

2- the spikes from inductive load are killing it

please advise from your knowledge and experience which is the most likely to happen ?

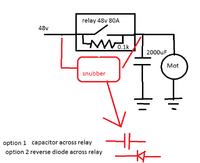

i attached a block diagram of the circuit , i have capacitor across the motor and i am using a 100ohm resistor across the relay to precharge the bulk capacitor before turning on the system !

the block in the red is my thoughts of solution for the problem , A capacitor or a reverse diode across the relay contact .

Note : the relay coil (0.1A) (is being switched by npn darlington from uC and is well protected )

the relay is acting weirdly after some uses , it gets stuck and needs to be switched on and off several times to run again . some times i hit the relay in order to work !! i have 2 theories for this problem : 1- relay is bad quality (chinease ) and is losing most of its life while soldering it at high temperature to the PCB !

2- the spikes from inductive load are killing it

please advise from your knowledge and experience which is the most likely to happen ?

i attached a block diagram of the circuit , i have capacitor across the motor and i am using a 100ohm resistor across the relay to precharge the bulk capacitor before turning on the system !

the block in the red is my thoughts of solution for the problem , A capacitor or a reverse diode across the relay contact .

Note : the relay coil (0.1A) (is being switched by npn darlington from uC and is well protected )