martin69

Newbie level 3

Hi everyone,

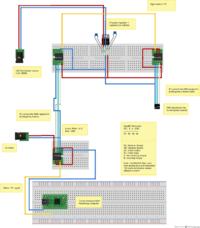

I'm trying to build large LED panels (3x128 LED modules) using WS2801 LEDs, with data coming from a Teensy 3.0 microcontroller. I'm having difficulties transmitting my Data and Clock signals between the different panels. The three panels have a separate power supply, so I can't transmit my signals directly because of ground problems.

I want to transmit my signals using RS485, so I got myself MAX485 chips, and am using them to symmetrize my signals. So far, it works without any problem if I want to get my signal to the first panel (Teensy output TTL -> Max485 => (RS485) => Max485 -> TTL).

However, when I want to get my signal to the following panel, I'm having a problem. I want to get Clock and Data coming out from the last LED, and RS485 them to the next panel - and this is precisely what does not work. What I want to do is : Teensy output TTL -> Max485 => (RS485) => Max485 -> TTL -> Max485 => (RS485) => Max485 -> TTL.

I know RS485 is in fact a 3-wire system, and I do have a common ground routed from my microcontroller.

I was thinking it might be a ground problem, but I don't know exactly where my problem comes from, since my reception MAX485 and my emission MAX485 are all powered by the same 12V power going to the LED (brought down to 5V, using a LM7805 regulator).

Note : the signal and clock signals output by my last LED are correct, if I route them directly to the following panel, it works alright, but I'm getting artifacts when all 3 panels are connected - that's why I switched to RS485

I'm trying to build large LED panels (3x128 LED modules) using WS2801 LEDs, with data coming from a Teensy 3.0 microcontroller. I'm having difficulties transmitting my Data and Clock signals between the different panels. The three panels have a separate power supply, so I can't transmit my signals directly because of ground problems.

I want to transmit my signals using RS485, so I got myself MAX485 chips, and am using them to symmetrize my signals. So far, it works without any problem if I want to get my signal to the first panel (Teensy output TTL -> Max485 => (RS485) => Max485 -> TTL).

However, when I want to get my signal to the following panel, I'm having a problem. I want to get Clock and Data coming out from the last LED, and RS485 them to the next panel - and this is precisely what does not work. What I want to do is : Teensy output TTL -> Max485 => (RS485) => Max485 -> TTL -> Max485 => (RS485) => Max485 -> TTL.

I know RS485 is in fact a 3-wire system, and I do have a common ground routed from my microcontroller.

I was thinking it might be a ground problem, but I don't know exactly where my problem comes from, since my reception MAX485 and my emission MAX485 are all powered by the same 12V power going to the LED (brought down to 5V, using a LM7805 regulator).

Note : the signal and clock signals output by my last LED are correct, if I route them directly to the following panel, it works alright, but I'm getting artifacts when all 3 panels are connected - that's why I switched to RS485