--BawA--

Advanced Member level 1

- Joined

- Nov 28, 2012

- Messages

- 479

- Helped

- 43

- Reputation

- 86

- Reaction score

- 42

- Trophy points

- 1,318

- Location

- Noida, INDIA

- Activity points

- 4,926

hi

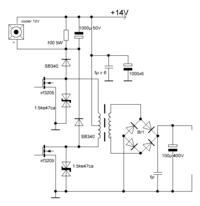

i have used 3+3 mosfet bank in my first stage of the inverter i.e dc to dc converter stage, so my question is how can protect my mosfets from burning? what protection circuit or components should i use along with the mosfets so that it does not burn in any case? i have made 3 times the mosfet banks but ,,after some time it get burned.....so please help me.....

i have used 3+3 mosfet bank in my first stage of the inverter i.e dc to dc converter stage, so my question is how can protect my mosfets from burning? what protection circuit or components should i use along with the mosfets so that it does not burn in any case? i have made 3 times the mosfet banks but ,,after some time it get burned.....so please help me.....