xeratule

Member level 4

- Joined

- Apr 4, 2009

- Messages

- 69

- Helped

- 1

- Reputation

- 2

- Reaction score

- 1

- Trophy points

- 1,288

- Location

- Istanbul / TURKIYE

- Activity points

- 1,975

Hi all,

I have ultrasonic cleaning transducer and I can measure its impedance with an impedance analyzer. Please correct me if I'm wrong from now on then:

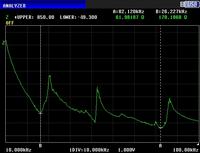

The resonance frequency is the frequency where its impedance is minimum. So when I apply various loads to the transducer, its resonance frequency shifts between 25khz - 30kHz. As the transducer is a piezoelectric crystal, its impedance has both active and reactive components (Z = R -jX). I try to get most active power from the transducer while power factor will not be less than 0.9. Lets say at frequency f1 the transducer has minimum impedance Z1 = R1 - jX1 . And at f2 it has minimum real impedance Z2 = R2 - jX2.

Here we have Z1 < Z2 and R2 < R1. If I match X1 and X2 with their complex conjugates ( ex: add series inductor) , that would result in: Z1 = R1-X1+X1 = R1 and Z2 = R2-X2+X2 = R2. This will make Z2 < Z1. As impedance is smaller, more current can pass through it. So can I have more active power where transducer operates better at f2 instead of f1? Or does it still operate better at its self resonance frequency f1 and not resonate well at f2?

Would like to have your valuable answers soon, thanks in advance.

Erhan

I have ultrasonic cleaning transducer and I can measure its impedance with an impedance analyzer. Please correct me if I'm wrong from now on then:

The resonance frequency is the frequency where its impedance is minimum. So when I apply various loads to the transducer, its resonance frequency shifts between 25khz - 30kHz. As the transducer is a piezoelectric crystal, its impedance has both active and reactive components (Z = R -jX). I try to get most active power from the transducer while power factor will not be less than 0.9. Lets say at frequency f1 the transducer has minimum impedance Z1 = R1 - jX1 . And at f2 it has minimum real impedance Z2 = R2 - jX2.

Here we have Z1 < Z2 and R2 < R1. If I match X1 and X2 with their complex conjugates ( ex: add series inductor) , that would result in: Z1 = R1-X1+X1 = R1 and Z2 = R2-X2+X2 = R2. This will make Z2 < Z1. As impedance is smaller, more current can pass through it. So can I have more active power where transducer operates better at f2 instead of f1? Or does it still operate better at its self resonance frequency f1 and not resonate well at f2?

Would like to have your valuable answers soon, thanks in advance.

Erhan