DeepOne

Advanced Member level 2

- Joined

- Feb 26, 2011

- Messages

- 632

- Helped

- 99

- Reputation

- 200

- Reaction score

- 100

- Trophy points

- 28

- Location

- 45N39E, Russia

- Activity points

- 0

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

regrettably, since several times (like year) that cores from TV deflection yoke in welding transformers is degrade and inductance of the transformer on their base decreases.TV deflection yoke is works very well

One of my welding devices is blowing up (in IGBT part) when i do fabrication of the awning for my car.expand on what you meant about core degradation

in this place else many programs for core calculations -core calculation program, very usefull

Hi. i know that this tread is old but I need help.

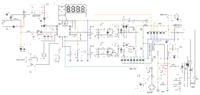

I have a problem with this welder project http://danyk.cz/svar_en.html

My IGBT burns out. I crashed 3 of them, 2 pc. IRG4PC40W and one pc of 200A igbt.

My question is : Why? I need air gap to my power transformer? If else tell me please.

Thanks

may be yes, may be not - that depends from many things.is this a good idea?