Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

We discussed this recently on this thread... Below GHz signals 90 degree corners don't make any difference.

Never heard of localised heating of traces on power designs and I've done some hefty one, I would like to see some citations regarding that, because it sounds like another PCB myth. Impedance, read up, Howard Johnson for one this thread for another.

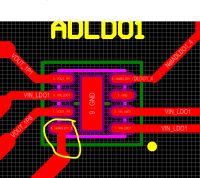

I would come out of the arc to remove the little nick in the copper and give a smoother line around the copper. Just a little neater and makes etching a little easier. The artwork is expanded slightly during manufacture to cater for etch back, so a smooth polygon shape is prefferable. its a little detail but its these that are important.