INGLE.SHUBHAM

Member level 1

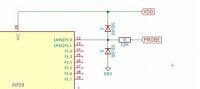

im doing a water level controller project and This circuit works off a 12V battery or 12V AC mains The sensors are connected to the circuit at appropriate terminals. negative terminal of a power supply gnd is at the bottom of the tank, sensor terminal L is just above the bottom of the tank and sensor terminal H is at the top of the tank.

Since gnd terminal is at the bottom of the tank, when the water level falls below sensor L, and micro controller is triggered and its output goes high. As a result, the Relay energises and the motor starts filling water in the tank. The motor remains ‘on’ even when the water level crosses sensor L.

As water in the tank rises to touch sensor H, the micro controller is retriggered as a result, its output goes low. The relay de-energises and the motor stops filling water in the tank. The motor remains ‘off’ even when the water level falls below sensor H.

As water is consumed and its level falls below sensor L, the motor restarts. Thereafter, the cycle repeats.

You can also manually start and stop the motor using switch this is the concept

but im facing some of the problems here i.e due to rusting of sensors when it is drop into water

1) DC voltage when the sensor is powered with the dc voltage the circuit is working fine according to the logic but the rusting of sensor is much faster, i.e the salt like white material is accumulated on the sensor here is the ckt and the pics of the demonstrations

sensors before connecting

sensors after connecting

so this is the result which i got from the above ckt, for dc voltage

2) AC voltage when the sensor is powered with the AC voltage the circuit is working fine according to the logic and there is no rusting across the sensor and here is the pics of the demonstrations for AC source

sensors before connecting

sensors after connecting

this is the result which i got for AC voltage

1) so my question is why the sensors are rusting in DC voltage and why not it is rusting in AC voltage and if i want to use in the dc voltage which sensors i should use so that it should not rust i want to use only metal type sensors not floating type sensor or else how i can prevent the rusting of sensors

2) if i go for the AC source i need to drop AC 12 to the water from the transformer if the transformer fails due to derating so the high vlt flows to the water which is very serious but the sensor quality will be good

so if you have any idea then please suggest to me how i can over come the above problem

THANK YOU

Since gnd terminal is at the bottom of the tank, when the water level falls below sensor L, and micro controller is triggered and its output goes high. As a result, the Relay energises and the motor starts filling water in the tank. The motor remains ‘on’ even when the water level crosses sensor L.

As water in the tank rises to touch sensor H, the micro controller is retriggered as a result, its output goes low. The relay de-energises and the motor stops filling water in the tank. The motor remains ‘off’ even when the water level falls below sensor H.

As water is consumed and its level falls below sensor L, the motor restarts. Thereafter, the cycle repeats.

You can also manually start and stop the motor using switch this is the concept

but im facing some of the problems here i.e due to rusting of sensors when it is drop into water

1) DC voltage when the sensor is powered with the dc voltage the circuit is working fine according to the logic but the rusting of sensor is much faster, i.e the salt like white material is accumulated on the sensor here is the ckt and the pics of the demonstrations

sensors before connecting

sensors after connecting

so this is the result which i got from the above ckt, for dc voltage

2) AC voltage when the sensor is powered with the AC voltage the circuit is working fine according to the logic and there is no rusting across the sensor and here is the pics of the demonstrations for AC source

sensors before connecting

sensors after connecting

this is the result which i got for AC voltage

1) so my question is why the sensors are rusting in DC voltage and why not it is rusting in AC voltage and if i want to use in the dc voltage which sensors i should use so that it should not rust i want to use only metal type sensors not floating type sensor or else how i can prevent the rusting of sensors

2) if i go for the AC source i need to drop AC 12 to the water from the transformer if the transformer fails due to derating so the high vlt flows to the water which is very serious but the sensor quality will be good

so if you have any idea then please suggest to me how i can over come the above problem

THANK YOU