Garyl

Full Member level 5

Hey

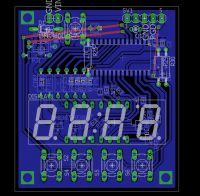

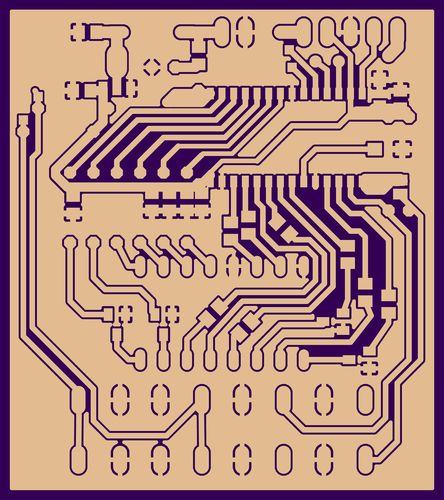

This is my 24F family clock/calendar with 7-segment display board:

It is using PIC INTERNAL OSCILLATOR and extra external oscillator for RTCC.

It has 4 digits 7-segmnent display, 3.3V LDO and 4 buttons and ICSP connector.

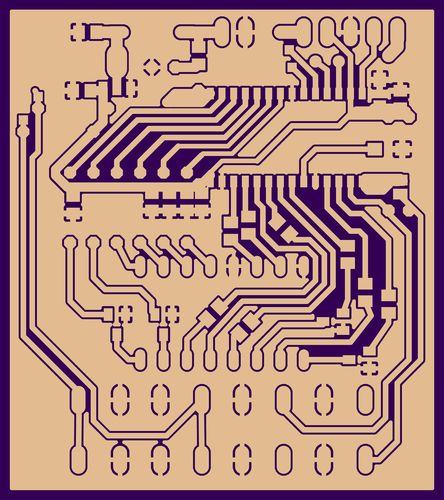

Can you tell me how can I improve my board layout and is the ground plane ok? Can I etch it already or is there something I can make better?

Thanks in advance!

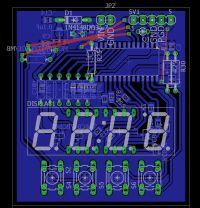

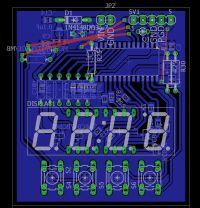

This is my 24F family clock/calendar with 7-segment display board:

It is using PIC INTERNAL OSCILLATOR and extra external oscillator for RTCC.

It has 4 digits 7-segmnent display, 3.3V LDO and 4 buttons and ICSP connector.

Can you tell me how can I improve my board layout and is the ground plane ok? Can I etch it already or is there something I can make better?

Thanks in advance!